RO3003 PCB 4-Layer 2.4mm Thick: High-Frequency Ceramic-Filled PTFE Laminates for Automotive Radar and 5G mmWave Applications

1. Introduction of RO3003

Rogers RO3003 high-frequency laminates are ceramic-filled PTFE composites designed for commercial microwave and RF applications. These laminates provide excellent stability of the dielectric constant (Dk) across a range of temperatures and frequencies, effectively eliminating the step change in Dk commonly seen near room temperature in PTFE glass materials. This characteristic makes them ideal for applications such as automotive radar (77 GHz), advanced driver assistance systems (ADAS), and 5G wireless infrastructure (mmWave).

2. Features

- Ceramic-filled PTFE composites from Rogers RO3003

- Dielectric constant of 3 ± 0.04 at 10 GHz/23°C

- Dissipation factor of 0.001 at 10 GHz/23°C

- Decomposition temperature (Td) greater than 500°C

- Thermal conductivity of 0.5 W/mK

- Moisture absorption of 0.04%

- Coefficient of thermal expansion (from -55 to 288 °C): X-axis 17 ppm/°C, Y-axis 16 ppm/°C, Z-axis 25 ppm/°C

3. Benefits

- Low dielectric loss, suitable for applications up to 77 GHz.

- Excellent mechanical properties at varying temperatures, ensuring reliable stripline and multilayer board constructions.

- Uniform mechanical properties across a range of dielectric constants, making it ideal for multilayer board designs and compatible with epoxy glass hybrid designs.

- Stable dielectric constant with respect to temperature and frequency, perfect for bandpass filters, microstrip patch antennas, and voltage-controlled oscillators.

- Low in-plane expansion coefficient that matches copper, enhancing the reliability of surface-mounted assemblies and stability in temperature-sensitive applications.

- Economical laminate pricing suitable for volume manufacturing processes.

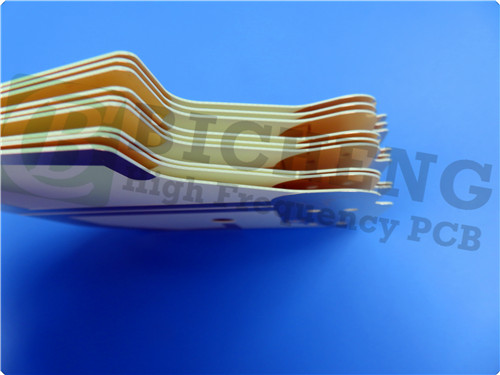

4. PCB Stackup: 4-layer Rigid PCB

- Copper Layer 1: 35 µm

- Rogers RO3003: 60 mil (1.524 mm)

- Copper Layer 2: 35 µm

- Prepreg RO4450F: 4 mil (0.101 mm)

- Copper Layer 3: 35 µm

- Rogers RO3003: 20 mil (0.508 mm)

- Copper Layer 4: 35 µm

5. PCB Construction Details

- Board dimensions: 190 mm x 90 mm (1 piece)

- Minimum trace/space: 4/4 mils

- Minimum hole size: 0.4 mm

- Blind vias from inner layer 2 to the bottom layer, via filled and capped.

- Finished board thickness: 2.4 mm

- Finished copper weight for inner and outer layers: 1 oz (1.4 mils)

- Via plating thickness: 20 µm

- Surface finish: Immersion gold

- Top silkscreen: Yellow

- Bottom silkscreen: Green

- Top solder mask: No

- Bottom solder mask: Green

- Countersunk holes required on the top layer at 90 degrees

- 100% electrical testing conducted prior to shipment

6. PCB Statistics

- Components: 27

- Total pads: 73

- Through-hole pads: 47

- Top SMT pads: 26

- Bottom SMT pads: 0

- Vias: 97

- Nets: 4

7. Type of Artwork Supplied

Gerber RS-274-X

8. Accepted Standard

IPC-Class-2

9. Availability :Worldwide

10. Some Typical Applications

- Automotive radar applications

- Global positioning satellite antennas

- Cellular telecommunications systems, including power amplifiers and antennas

- Patch antennas for wireless communications

- Direct broadcast satellites

- Datalink on cable systems

- Remote meter readers

- Power backplanes